2.8L LWN

Small Footprint. Big Impression.

The Duramax 2.8L is the cleanest diesel truck engine ever produced by General Motors, and it meets some of the toughest U.S. emissions standards, thanks in part to a cooled Exhaust Gas Recirculation (EGR) system.

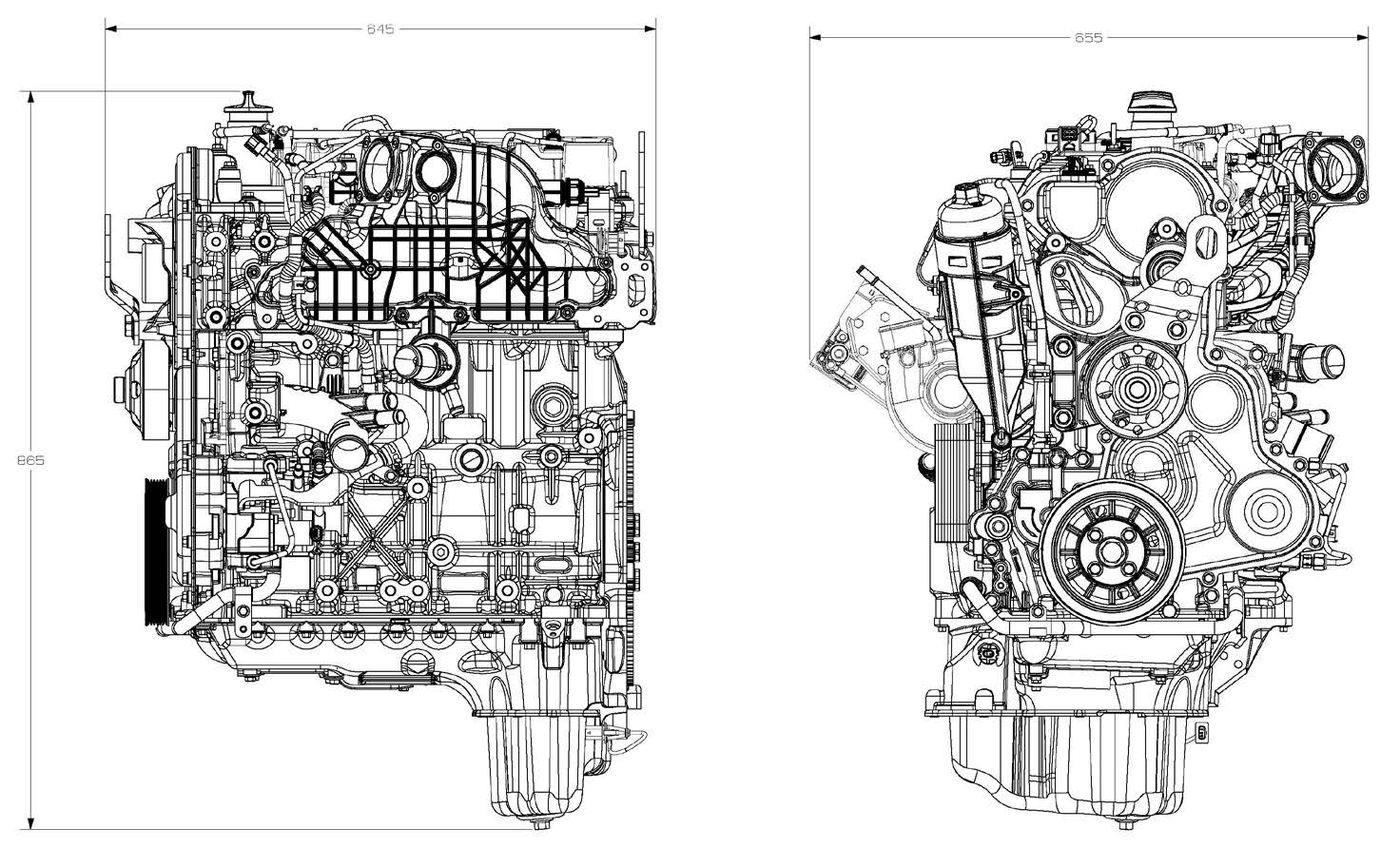

The engine is part of GM’s global family of turbo-diesel four-cylinder engines and features a variable-geometry turbocharger for optimal power and efficiency across the rpm band and a balance shaft for smoothness.

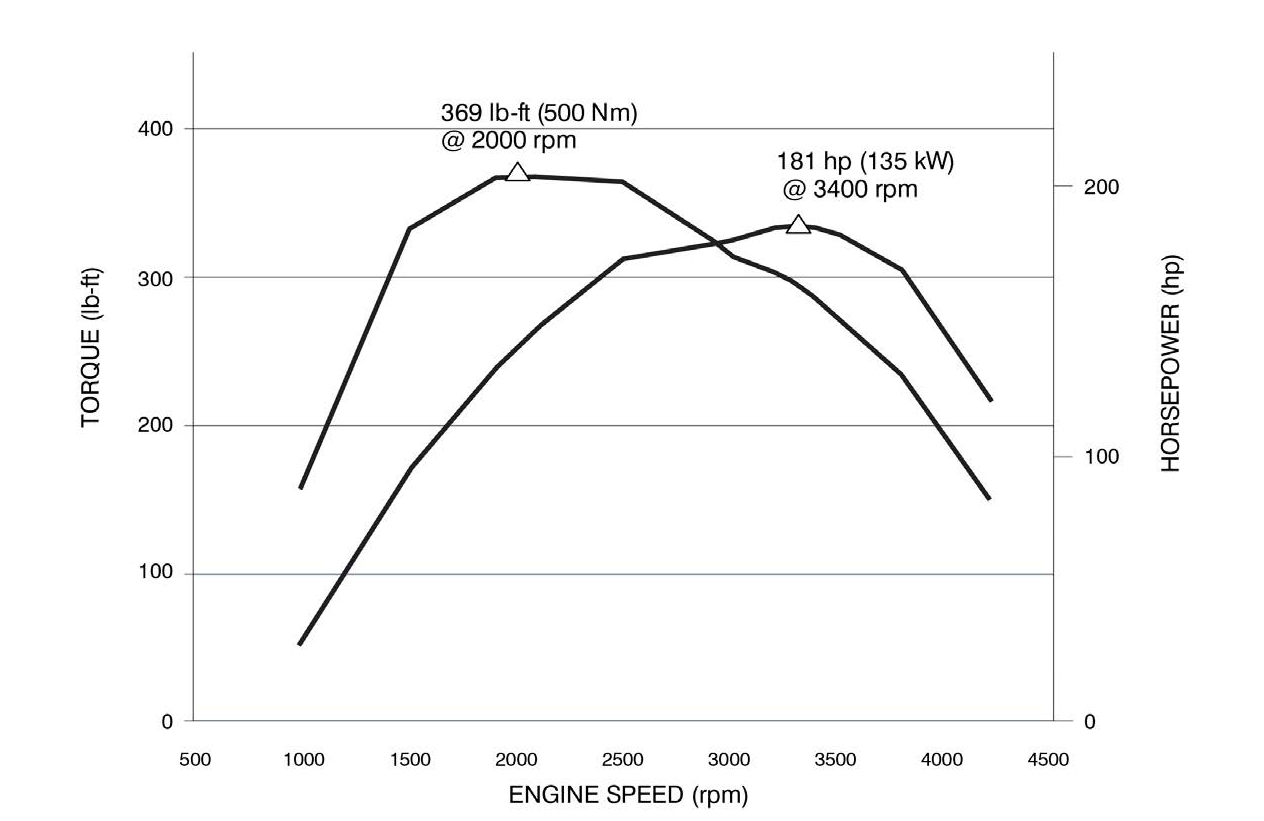

A broad torque band makes the 2.8L Duramax very powerful at low rpm, while the turbocharged performance provides a confident feeling of immediate and smooth horsepower on demand.

State-of-the-art Technologies

Cast-Iron Engine Block

- Oil jet-spray piston-cooling feature enhances durability, ensuring piston robustness at critical operating conditions.

- Forged-steel crankshaft anchors rotating assembly, reducing noise and vibration, which in turn leads to enhanced durability.

Aluminum Pistons

- Lightweight aluminum pistons result in less mass inside the engine leading to more efficiency, decreased vibration, and bolstering performance at high rpm.

Cylinder Head

- Aluminum cylinder head cast with advanced semipermanent mold technology providing excellent strength and reduced machining with optimal port flow.

- Heat-treated casting reduces residual stress, enhancing engine durability.

- Four-valve architecture ensures optimized breathing of the engine and clean combustion process.

- Includes premium valve seat, valve guide, and valve materials, ensuring good durability without required adjustments found on other engines.

Rotating Assembly

- Features friction-reducing polymer coating on skirts to help reduce friction.

- Less piston weight results in less reciprocating mass in the engine – resulting in less inertia for greater operating efficiency.

Additional Features

- Iron cylinder block and aluminum DOHC cylinder head

- Oiling circuit that includes a dedicated feed for the turbocharger to provide increased pressure at the turbo and faster oil delivery

- Piston-cooling oil jets

- Balance shaft that contributes to smoothness and drives the oil pump

- Laminated steel oil pan with upper aluminum section that contributes to engine rigidity and quietness

- B20 biodiesel capability

Specifications

| COMBUSTION SYSTEM | Compression ignition |

| INDUCTION SYSTEM | Variable-geometry turbocharger |

| DISPLACEMENT | 2776 cc |

| ENGINE ORIENTATION | Longitudinal |

| COMPRESSION RATIO | 16.5:1 |

| VALVE CONFIGURATION | Dual overhead camshafts |

| VALVES PER CYLINDER | 4 |

| VALVE TIMING | Fixed |

| ASSEMBLY SITE | Rayong, Thailand |

| FIRING ORDER | 1 - 3 - 4 - 2 |

| BORE X STROKE | 94.00 x 100.00 mm |

| FUEL SYSTEM | Direction-injection common rail |

| FUEL TYPE | Diesel/B20 biodiesel compatible |

| ENGINE MASS | 236 kg (520 lb) |

| HORSEPOWER | 181 hp (135 kW) @ 3400 rpm* |

| TORQUE | 369 lb-ft (500 Nm) @ 2000 rpm* |

| MAXIMUM ENGINE SPEED | 5000 rpm |

| EMISSIONS CONTROL | Close coupled diesel oxidation catalyst, selective catalytic reduction with urea injection, diesel particulate filter, cooled exhaust gas recirculation valve, positive |

| EMISSIONS STANDARD | crankcase ventilation |

| BLOCK | Tier 3 BIN 125/ULEV 125 (Colorado/Canyon) Tier 3 BIN 250/ULEV 250 (Express/Savana) |

| CYLINDER HEAD | Gray cast iron |

| INTAKE MANIFOLD | Aluminum |

| EXHAUST MANIFOLD | Composite |

| CRANKSHAFT | Cast iron |

| CAMSHAFT | Forged steel |

| CONNECTING ROD | Powdered metal/sintered lobes |

*As tested in Chevrolet Colorado.